Yes, there is more turning clearance with our hitch than most of the leading brands.

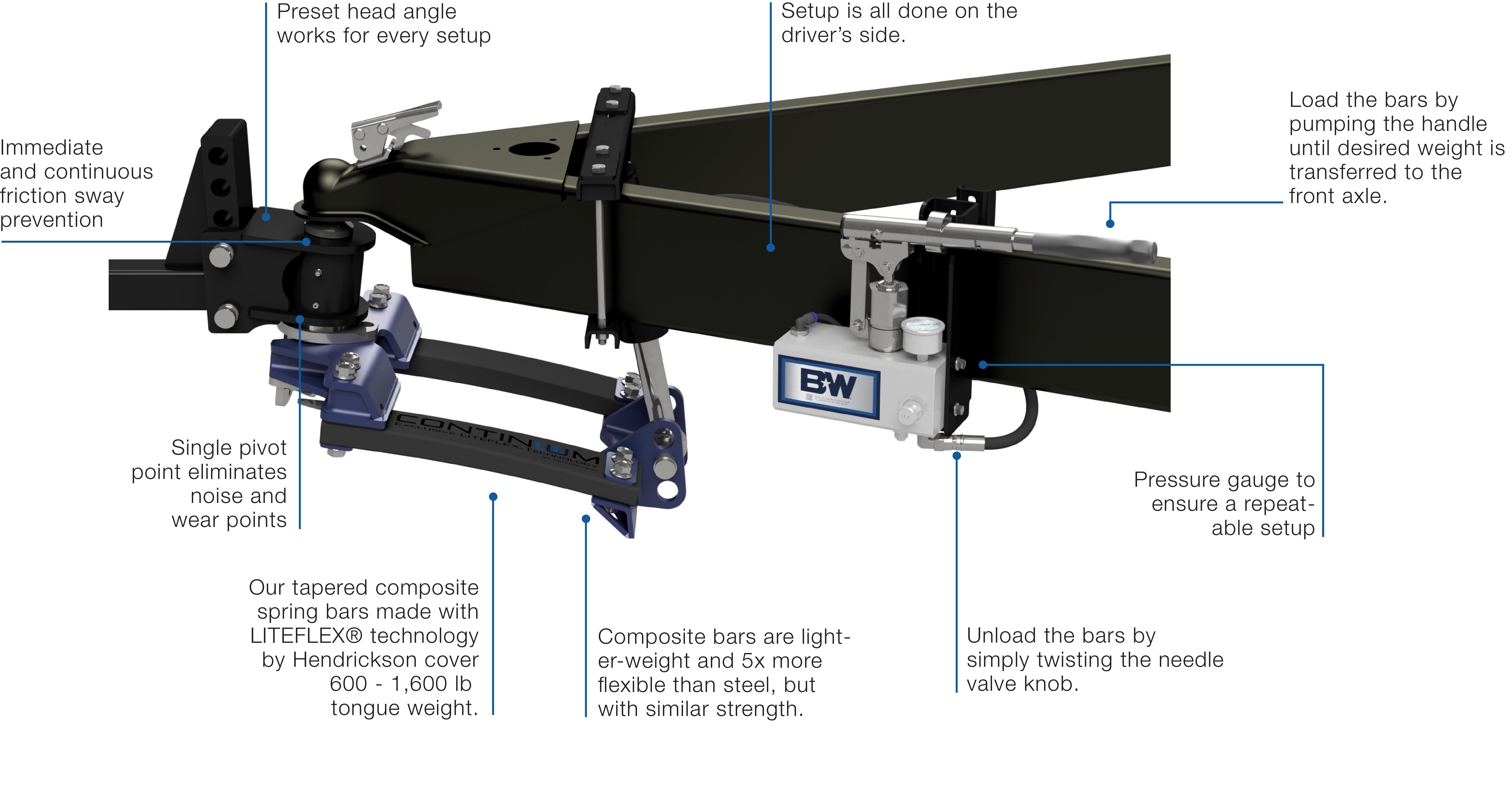

Because our bars are made of composite, not steel, we are able to cover 600-1600 lb tongue weights with the same bars. We partnered with Hendrickson, the world leader in suspension systems for heavy duty trucks. Their LITEFLEX composite bars are five times more flexible than steel with the same strength (and much lighter!) You can trust them to hold up, too, since they are corrosion resistant.

Yes. The continuum has as much, or more friction sway control built into it as the leading brands, although we prefer the term ‘sway prevention.’ Because our bars are always ‘loaded,’ our friction sway prevention is immediate and continuous (hence, the name Continuum.) This ‘loading’ or ‘stiffness’ can help with handling, but in our opinion, sway control components do little to stop sway once it starts.

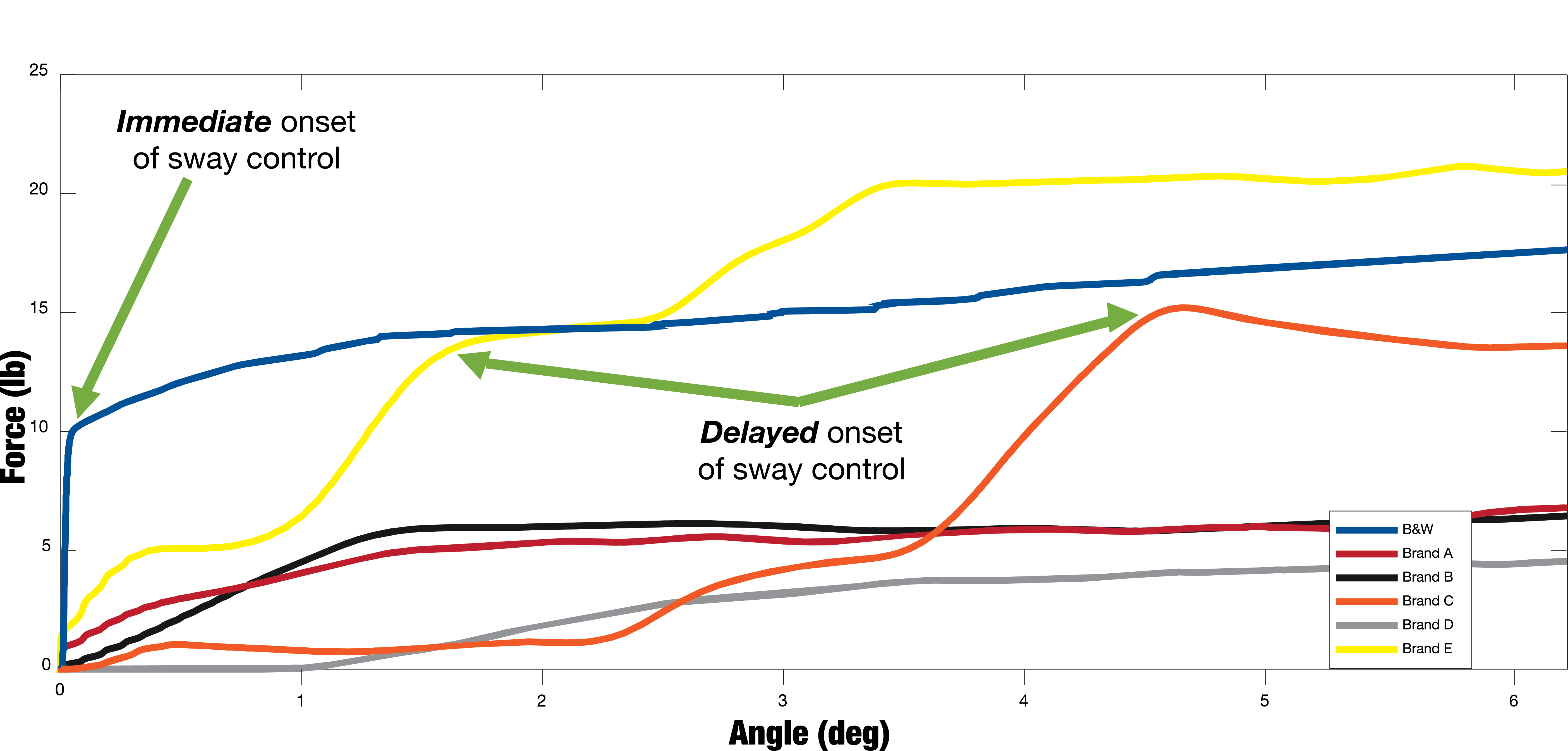

Over the years that we were developing our weight distribution hitch, we studied sway control in an attempt to design the best system. We studied all of them; 2-point, 4-point, adaptive, self-adjusting, self-centering and all the buzz words the industry had invented. We conducted an experiment with the top WD hitches on the market.

We set up a truck and trailer in a warehouse and used air castors under the tires to eliminate the ground friction. We then took readings of the hitch’s resistance to sway, or the force necessary to overcome the friction sway control components of each brand of hitch.

We learned that all brands provide some level of sway control, but that it takes very little force to overcome them. Some brands don’t load until the angle of the trailer is 2-4 degrees or more. On a 25-foot trailer, this equates to 3-5 feet, which means your trailer will be significantly outside your lane before it has a chance to be helpful.

The amount of force required to overcome these devices is low, for instance

In most cases, our hitch can be installed in 30 minutes or less, using only a 9/16” wrench. The head angle of the hitch is pre-set, and the bar assembly is pre-assembled. Steps to install the hitch include: Leveling the trailer, setting the height of the hitch ball, mounting the pump and cylinder to the trailer frame, and pinning the cylinder to the spring bar assembly.

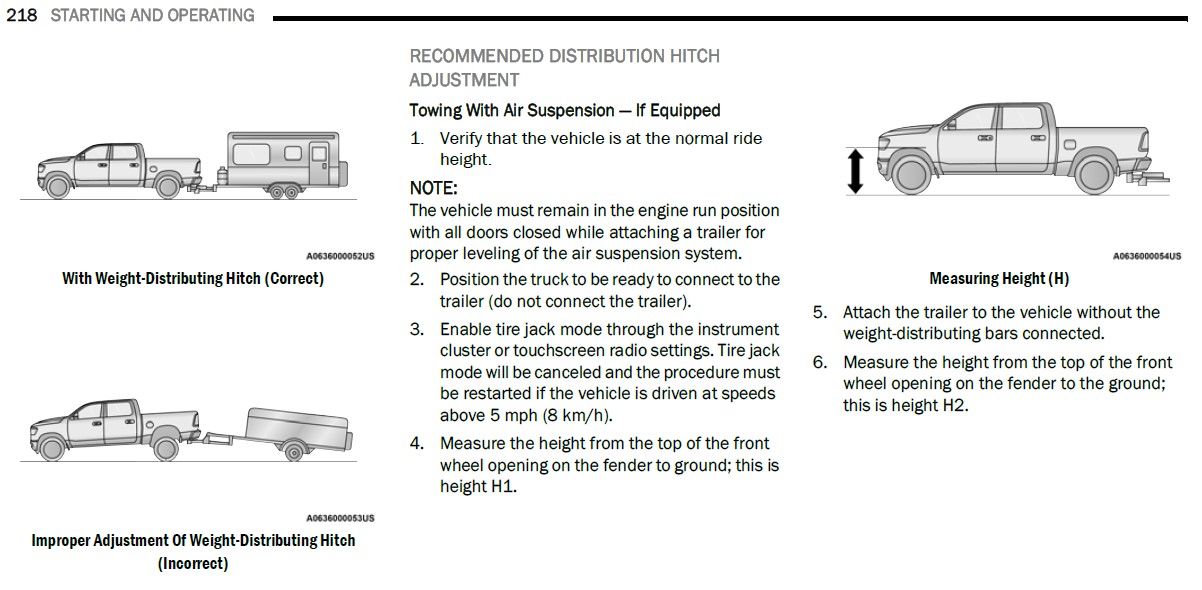

With bumper towed trailers, it creates a problem if there is too much of the weight on the rear axle of the tow vehicle. Weight distribution hitches move weight to the front axles to help with steering and braking. While traditional WD hitches are either ‘loaded’ or ‘unloaded’, the Continuum uses a pump to allow you to fine tune the amount of weight you are moving to better control your towing experience.

Weight distribution ‘rules of thumb’:

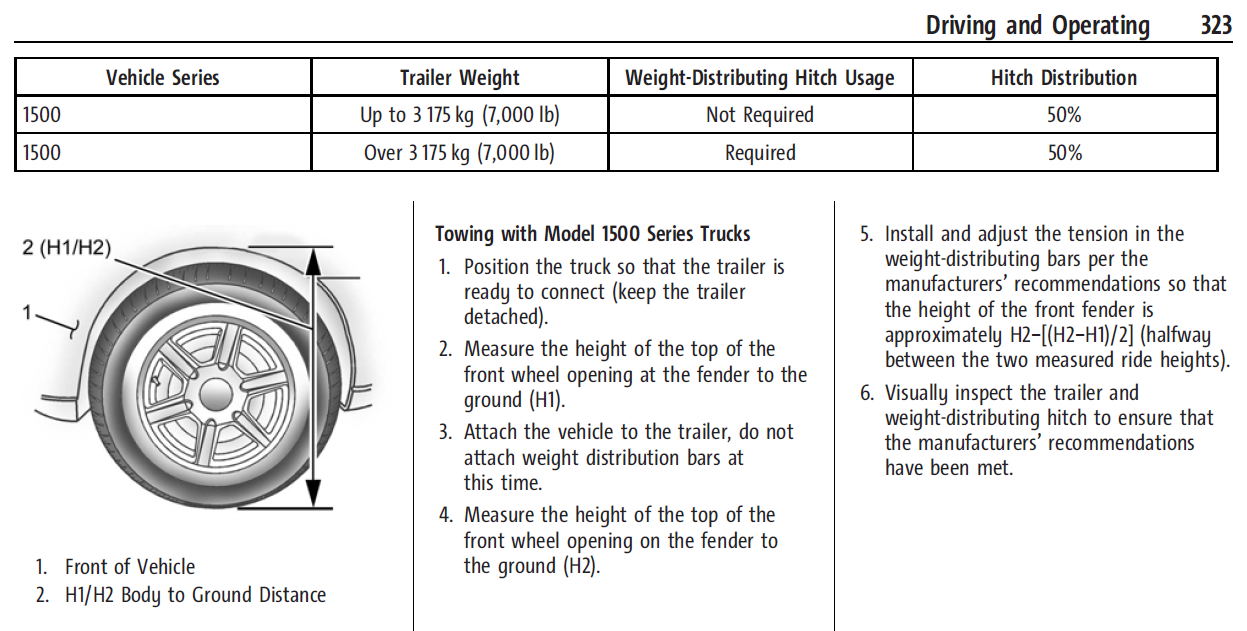

The need for a WDH is usually mentioned in the tow vehicle owner’s manual. For instance, some trucks require weight distribution for any trailer over 5,000 lb.

If your trailer’s weight (GTW) is more than 50% of your tow vehicle’s weight (GVW)

If your tow vehicle sags when you hook the trailer to it

If you find it difficult to steer or stop

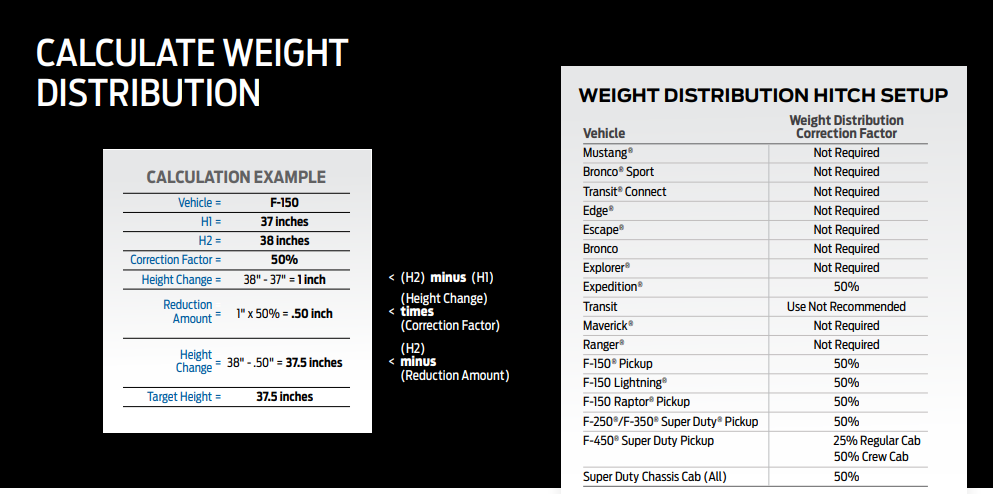

Even though vehicle manufacturers specify their recommended Front Axle Load Restoration, sometimes it isn't explicitly called FALR. They all use their own terminology (for instace, Ford calls it "Weight Distribution Correction Factor", and Chevrolet calls it "Hitch Distribution" Ram doesn't give a percentage, but they indicate that your final measurement needs to be 2/3 restored (67%.)

Most pickup trucks are going to be closer to 50% and some lighter vehicles recomment 100% A good rule of thumb is to use 50-100% restoration.

Here are some examples of sample data found in owner's manuals:

Not really. Some systems have steel bars that need to be ‘loaded’ on each side of the trailer with a tool. Our system is loaded from the driver’s side by pumping a handle and watching weight move to the front axles.

With other hitches, any change in your trailer or tongue weight might require a hitch head adjustment. Large adjustments might require different bars, minor adjustments might mean adding or subtracting washers or other adjustment in the head. Our head angle is set, our bars are rated from 600-1600 lb tongue weights, and our adjustments are small and allow precise control. If your trailer isn’t handling the way you like, pull over and pump the handle again to add weight to the front axles, easy as that.

That is where this hitch really shines! It’s important to make the proper weight adjustment when your load changes, but other hitches make it difficult to do that. With our hitch, a couple more pumps of the handle will transfer more weight to the front axles, without changing out bars or complicated adjustment to the head.

This hydraulic system is what you see on tractors and heavy construction equipment. We designed this hydraulic system specifically for this application, from the pump cartridge, needle valve, pressure relief valve and pressure gauge. It's also a closed loop system which prevents contamination. Some of the hydraulic components you find on commercial airliners, for instance. The zero-leak check valve used to maintain pressure on landing gear on commercial aircraft is the same we’ve used to hold pressure and maintain proper weight distribution. The needle valve is also used in aerospace. With metal on metal contact, there is no o-ring to degrade over time causing pressure loss. The cylinder is the same used on construction equipment. The air fittings and hoses are DOT approved and used on over the road trucks. Our system has been tested from -40°F to 150°F.

Max pressure on the hydraulics is around 3000 lbs, but the max reset pressure is set to 2500 lbs, so you will never reach that maximum. Pump it past 2500 lbs and you will hear the air escaping from the pressure relief valve.

Our bars do look low to the ground until they are loaded properly. We performed 100,000 miles of real-world testing with our design and have not had any issues with ground clearance except in extreme road conditions. Usually, the rear of the trailer or the leveling jacks will hit the ground before the hitch has any ground clearance issues. As with most WD hitches on the market, it's possible that some part of the hitch will drag when faced with especially steep dips in the road or entrances.

A sway control hitch is a weight distribution hitch that includes a feature that the manufacturer calls ‘sway control.’ Recently, it seems the terms are used interchangeably, although in our opinion, sway control is dubious terminology. More on that later.

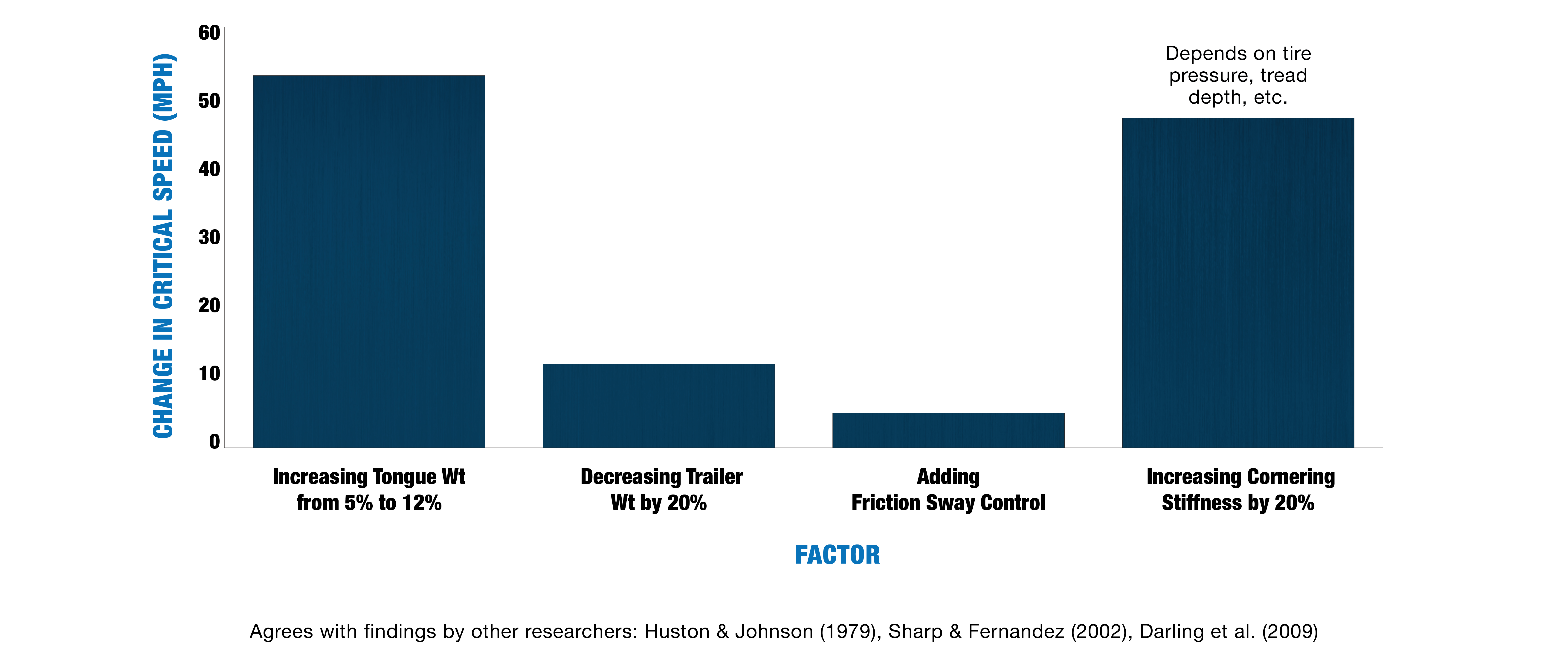

The best thing to do is focus on sway prevention. Safe towing happens when the following things are in place.

Driving the proper speed. Some truck and trailer combinations will become inherently unstable at a critical speed. This speed varies depending on your exact setup. You will also need to slow down in windy or slippery conditions.

Tongue weight is at the recommended amount. 10-15% usually. It is important to be over 10%.

Tire pressure and tread depth are good. Also need to make sure the tires are rated properly (for both the tow vehicle and trailer). Sidewall stiffness can greatly affect the sway characteristics.

The tow vehicle is sized appropriately for the trailer

Our findings agree with a lot of the literature out there, as well.

Huston & Johnson (1979),

Sharp & Fernandez (2002),

Darling et al. (2009)

In most cases, yes. It will depend on the set up (frame design, tailgate length, trailer jack size, etc.)

Yes, the spring bar assembly is easily removable to allow you to tow with just the ball mount if you have a trailer that does not need weight distribution.

You can also constrain the spring bar assembly between the bottom of the frame and the spring bar holder accessory on the jack foot by raising the jack until it is tight against the frame.

The Continuum fits 5” and 6” frames without a center frame rail. (It will also fit 4” and 7” frames with longer or shorter cylinder mount hardware). You will need 2” of clearance in front of to install the frame brackets. We have a bracket that, when added, allows our hitch to be used with underslung couplers.